Our sensor designs are based on the textile Matrix design by Maurin Donneaud: https://matrix.etextile.org/

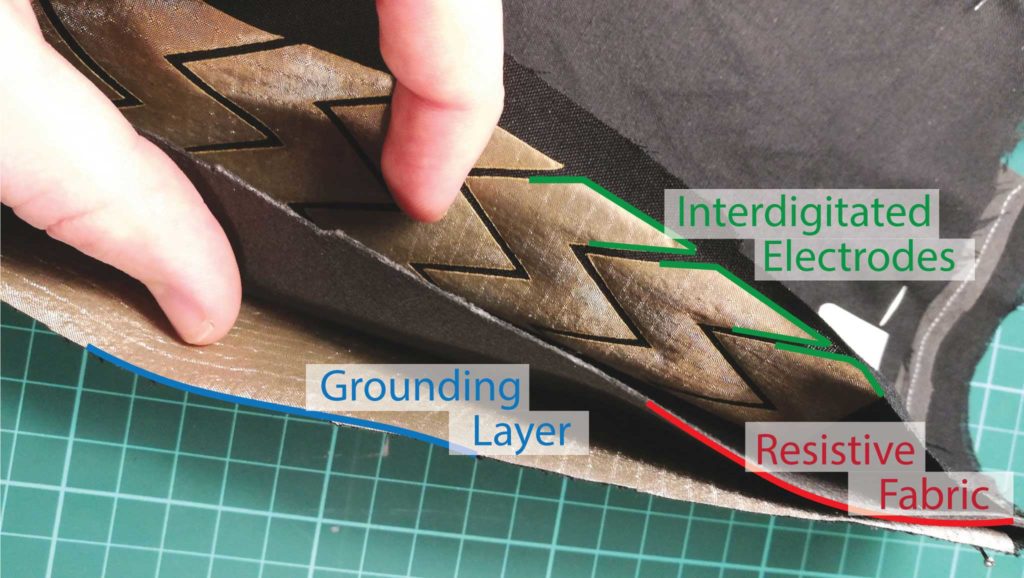

We implemented it in a similar fashion as demonstrated with zPatch: https://zpatch.github.io/

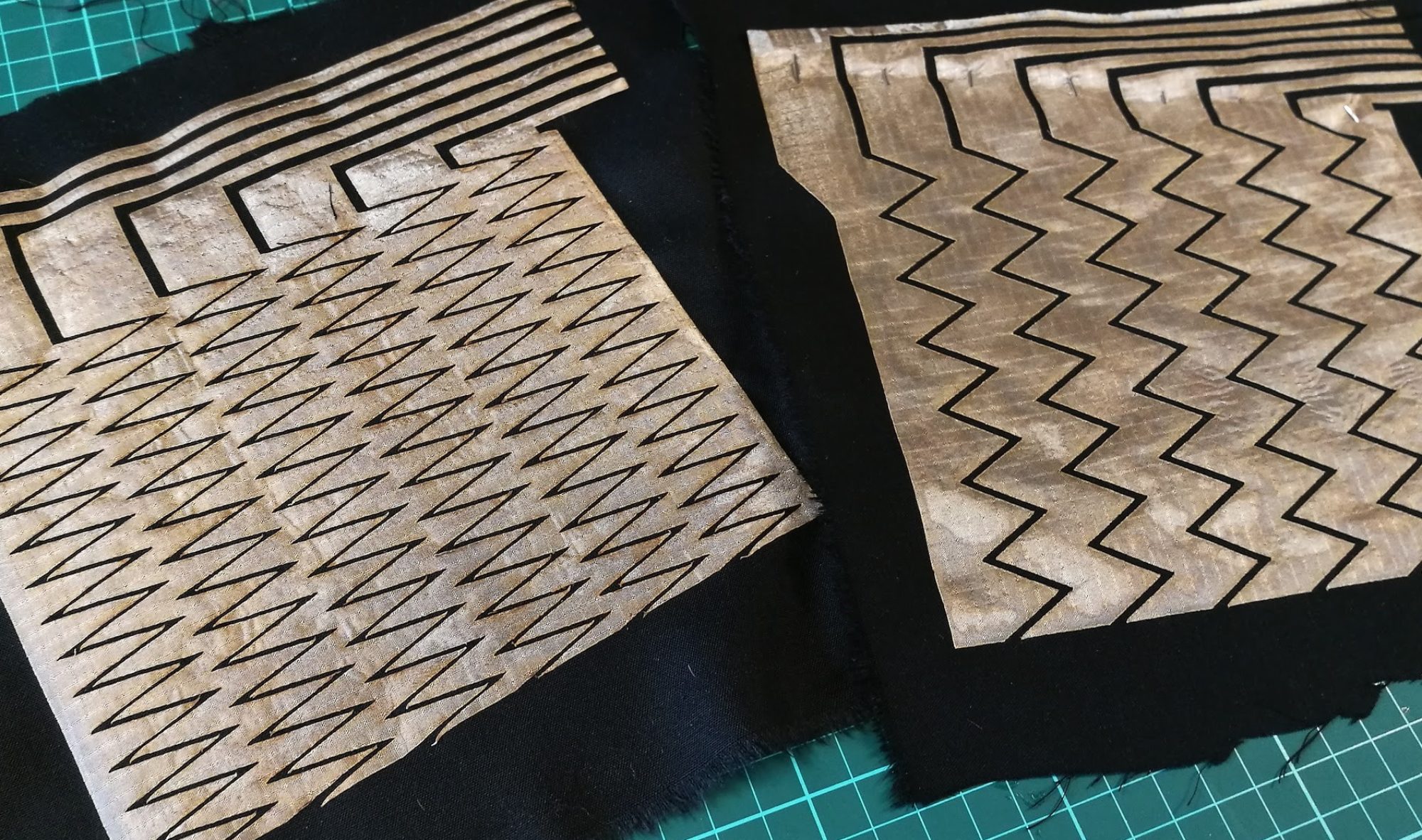

We used conductive ripstop for creating the sensing electrodes. We prepared it by ironing dual-sided fabric bonding to the the Ripstop. Then, using dual-sided scrapbook adhesive we glue the ripstop to an MDF board (bonding glue side up). We insert the board with the ripstop into the laser-cutter and cut the pattern. Once we remove the MDF and ripstop from the laser cutter, we gently peel off all excess material from the board, so that only the electrodes remain glued to the board. We then place a second piece of textile – this time non-conductive – on top of the electrodes and iron it in place. Once the bonding has securely connected the electrodes to the non-conductive fabric, we pull both fabric layers off the MDF board.

This method of transferring the cut design allowed us to create more precise patterns, as we did not need to manually arrange the electrodes on fabric backing. We used piezo-resistive, non-woven fabric by Eeonyx (20kΩ per square) for our resistive layer.

A nice overview of piezp-resistive materials is provided by KOBAKANT.